3D Modeling

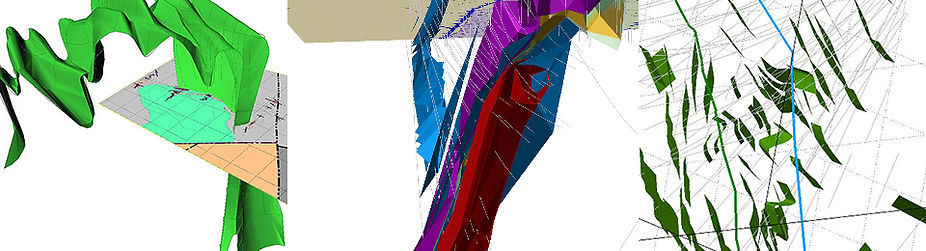

HCOV Global integrate on-site structural mapping and analysis of complex targets with the design and production of 3-D structural models, fully interpreted and linked to the exploration program. Using a combination of structural analysis, core-to-core plating, and implicit modeling (RBF-based software) we specialise in complex geometries that are unsuitable for either section-to-section orthogonal extrapolation, or for the wholesale application of implicit modeling software alone.

Modeling programs can be on a continuing development basis as part of our one-on-one consultancy service, or as a turnkey package with one or more HCOV Global Principals involved, and other associates as required.

Turnkey package quotes are a two stage process:

1. – a short on-site program (7-14 days) to assess the scope of the problem and provide initial analysis of the structure and its relationship to mineralisation. This short study may be all that is needed to enhance understanding of the project and guide future exploration without further commitment.

2. – submission of a turnkey quote for a full 3-D model. The cost and time required depends on the nature of the problem, the precision of the required model, the volume of available data, and the amount of new data or mapping that needs to be collected. 3-D geological models can be produced in a number of ways, each with advantages and disadvantages:

-

Our preferred approach in complex areas is to use a plating construction, where surfaces are extrapolated through known drillhole and surface intersections based on all available structural and geological data. This approach leverages our own structural experience and produces the most confident result, but is the most time consuming.

-

We use RBF–based software (Implicit modeling) to produce elegant surfaces in areas of simple geology where there is a large amount of control data. This procedure can be very fast, and produces very smooth surfaces, but the results can be of lower confidence because of the nature of the algorithm, which is based on achieving a smooth reasonable fit, as opposed to a geologically constrained fit). RBF-based modeling (we currently use Micromine’s Implicit Modeller and Leapfrogbfor this) can also be used to smooth out and extrapolate the plating models.

Modeling projects that we have undertaken include:

-

Crixas Mine, Brazil (Rod Holcombe; Tim Coughlin) – modelled using serial sections and Leapfrog. This model, which was based on +50km of rapid relogging took two months)

-

Veduga project, Siberia (Rod Holcombe) – modelled using FracSys then passed into Datamine. This complex model, based on the plating method, evolved over several years and involved many kms of core and trench relogging.

-

Angostura project, Colombia (Rick Valenta) - modelled using Leapfrog and Micromine. This model required the construction of an intersecting vein system of over 100 individual tagged veins with specified overprinting relationships, based on a combination of field, core and underground data.

-

Drazjna project, Kosovo (Rod Holcombe, Mentor Demi) – modelled using FracSys passed into Datamine. This model, based on core and underground logging, was produced relatively quickly.

-

Morning Star mine, Australia (Rick Valenta) - modelled using Leapfrog and Micromine. Multiple subhorizontal and intersecting reefs cutting a complexly faulted and displaced diorite dyke system.

-

Prominent Hill, Australia (Rod Holcombe) – modelled using Micromine. (This included two modelling projects that were eventually merged: a near-mine model and a regional (+50km) model. It was based on rapid relogging of ~100km of core over several years.

-

Golden Dyke, NT, Australia (Rick Valenta) - modelled using Geomodeller, Leapfrog and Gocad. Based on a detailed aeromagnetic interpretation, this was a regional model in an area of complex refolding and later faulting.

-

Amulsar project, Armenia (Rod Holcombe, Mentor Demi) – modelled using both Micromine and Datamine. This model was of a large complex area and was based on a considerable relogging database. The modelling was by the plating method. The RBF method was tried but has so far not been able to reproduce adequately the complex structure observed.

-

Mallee Bull Project, Australia (Rod Holcombe) – modelled using Micromine. This was a quick small-project model of relatively simple geology based on reappraisal of existing core logs. It was amenable to both plating and RBF modelling.

-

Numerous small, quick models have been produced in a number of projects to illustrate the local structure defined by mapping and GIS modelling, and to provide a guide for in-house resource modelling. These include projects in Australia, Laos, Canada, and Uruguay.